LatticeAx Indent and Cleaving Solutions

Go beyond what is possible with scribing, Learn more about LatticeAx Systems

Cleaving experts and novices are challenged every day to improve success rates, targeting accuracy, and throughput and to achieve better productivity. LatticeAx® systems were developed to meet these goals using smart mechanics coupled with microscope vision. The engine of the product line is the 120 base micro-line indent and cleaving system. With the 225 and 420 systems the vision and industrial platforms are integrated to achieve high cleaving accuracy and reproducibility without the complexity, sample restrictions and cost of automated instruments.

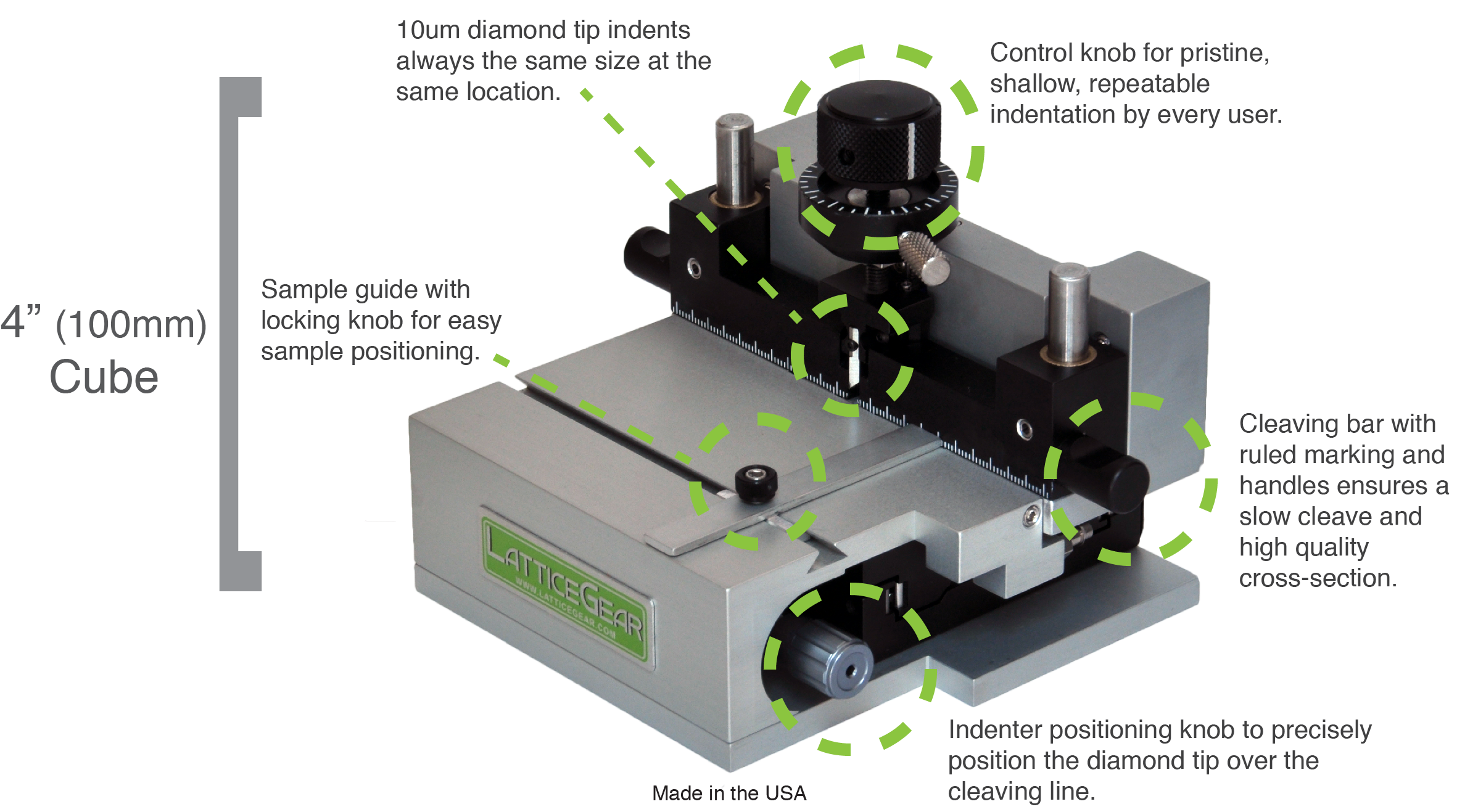

The patented LatticeAx® base platform is used by research institutions and industrial laboratories who need a cleaving tool without excessive constraints with respect to sample dimensions and type but also need high quality results and of course a cost effective solution. Their users are experts in getting the best out of the LatticeAx 120 and continue to surprise us with innovative uses for the tool.

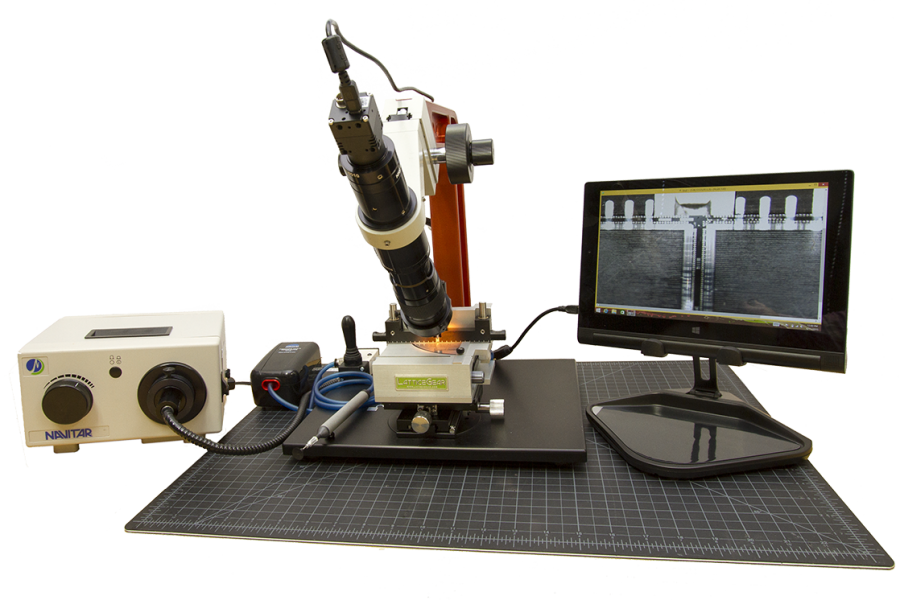

When sample preparation procedures are integrated in a laboratory's workflow speed and ease of use and in some cases accuracy are important. The LatticeAx® 225 adds an industrial platform with an optical microscope to the 120 base, making the 225 a cleaving system. The microscope vision allows the micro-line indent to be placed with ±20 microns targeting accuracy. The industrial setup enables multiple users to achieve the same results day after day.

LatticeAx 225

|

LatticeAx 420

|

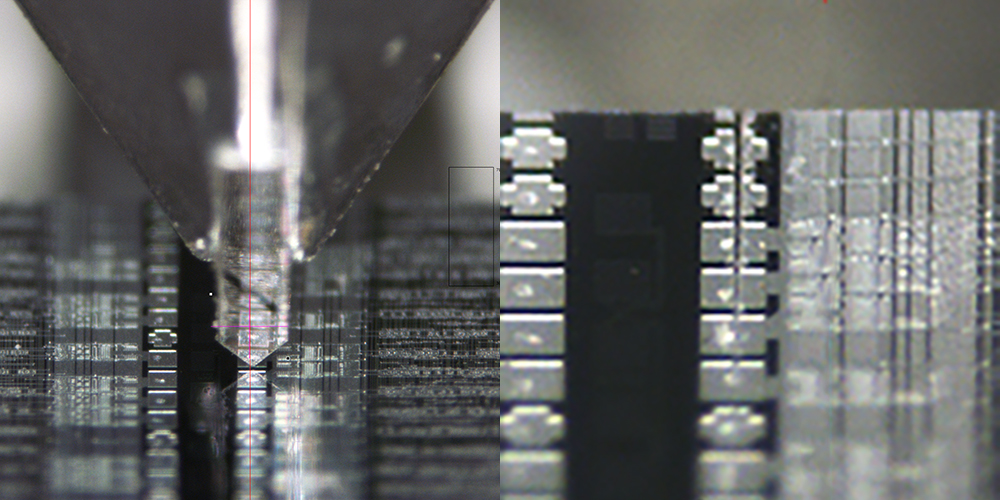

The LatticeAx® 420 is utilized in failure analysis, R&D laboratories and Nanofabrication facilities worldwide. It is LatticeGear’s highest performance cleaving solution delivering both high accuracy cleaving (HAC) and high quality reproducible results. It integrates LatticeGear’s custom industrial platform and research grade vision package with 4-μm optical resolution and precise focus control to cleave with 10-μm accuracy in <5-min.

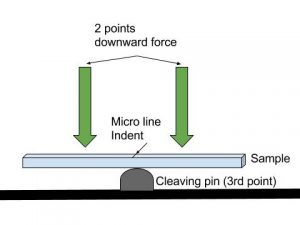

Figure 3 3pt cleaving method integrated into the LatticeAx®

Indenting and Cleaving with the LatticeAx®

Two steps are required to cleave a sample.

Step 1. Weak point creation

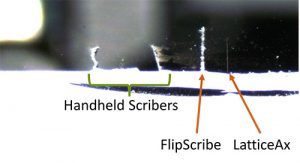

The weak point is a defect created on the sample. It will be the initiation point for the cleave. It is not possible to split a substrate into two pieces without first making a weak point using a diamond scriber or indenter. The weak point is made on the edge of the sample and is very important as it defines the accuracy and quality of the cleave because the cleave propagates from the weak point. If the weak point is made at an angle, is wide, or causes fractures both accuracy and quality of the cleaved surface will be negatively effected. On the LatticeAx the cleave is initiated by the microline indent (750 - 1000 µm long) (See Figure 2). Key to targeting accuracy and edge quality, the indenter can be positioned in ±5µm steps and depth is controlled by the calibrated clock dial knob. Figure 1 is a comparison of indents and scribes made using a variety of handheld and machine tools including handheld scribers and LatticeGear machines.

Step 2. Cleaving

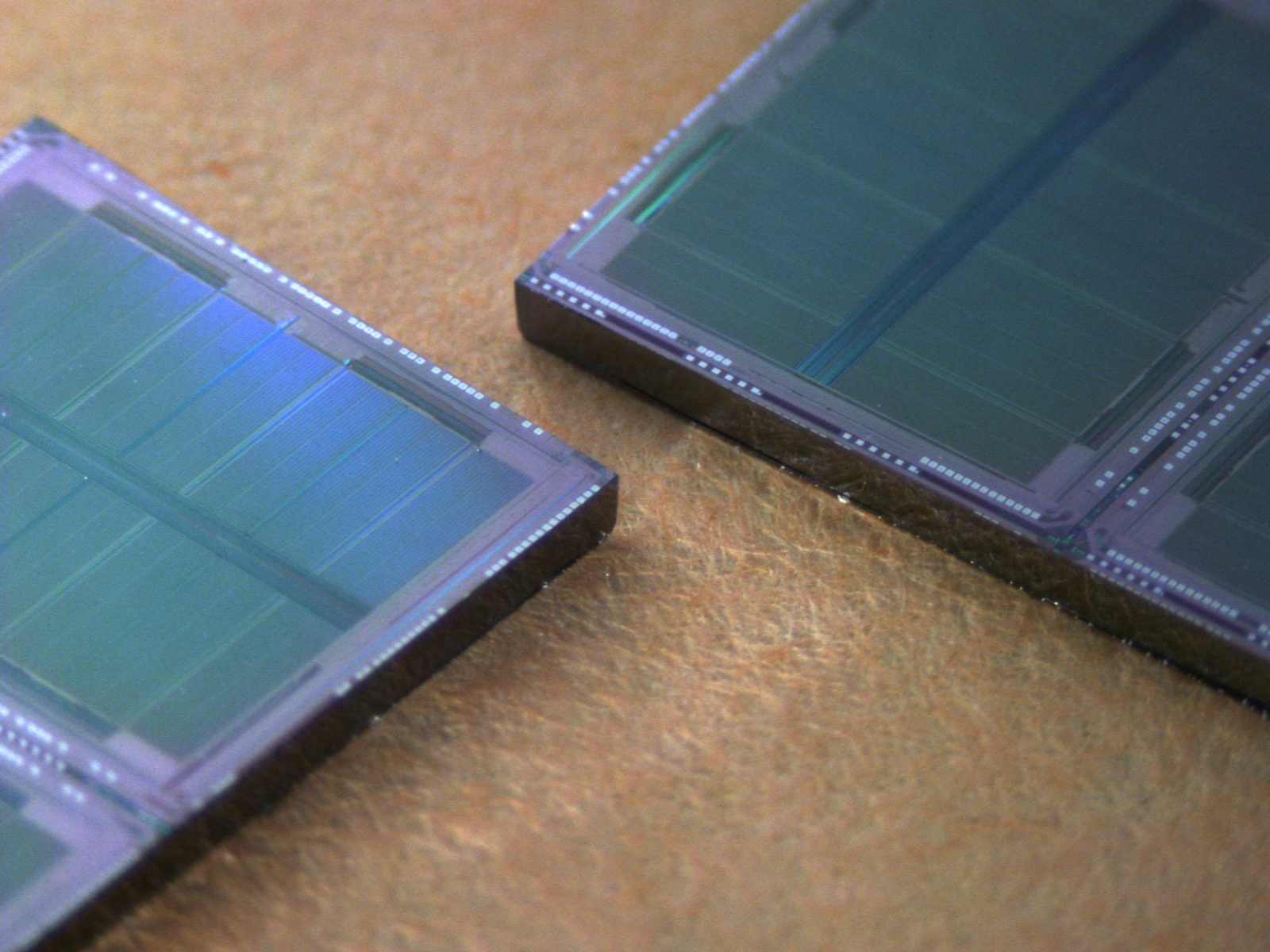

The second step in preparing a cleaved sample is cleaving. Cleaving occurs by creating stress on the weak point. The cleave is then initiated and propagates across the sample. Using 3pt cleaving the sample is cleaved (Figure 2). The fixed stress points designed into the LatticeAx and the ability to control the pressure on the sample during the cleaving step allow a slow cleave resulting in high quality cleaved edges (Figure 4).

Watch the video to see how it works!