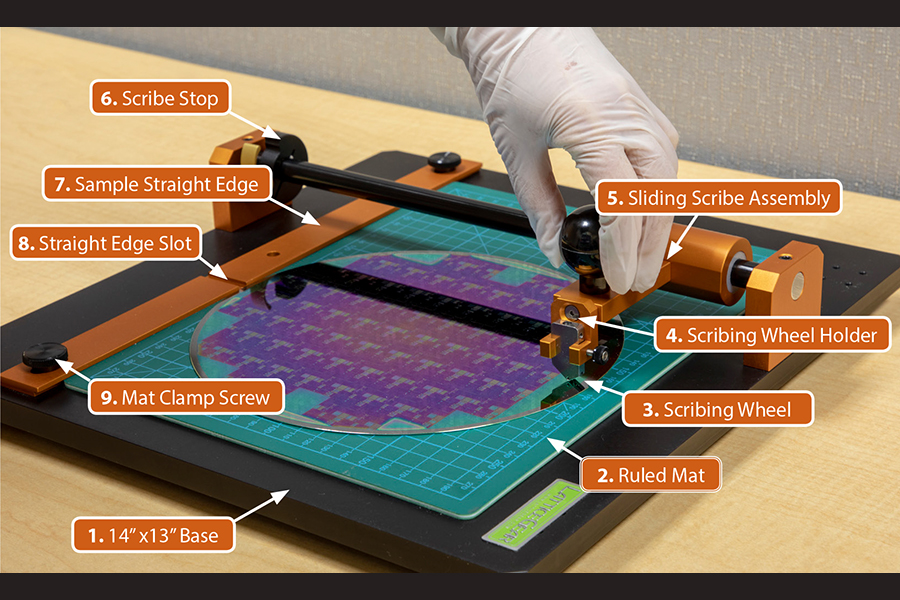

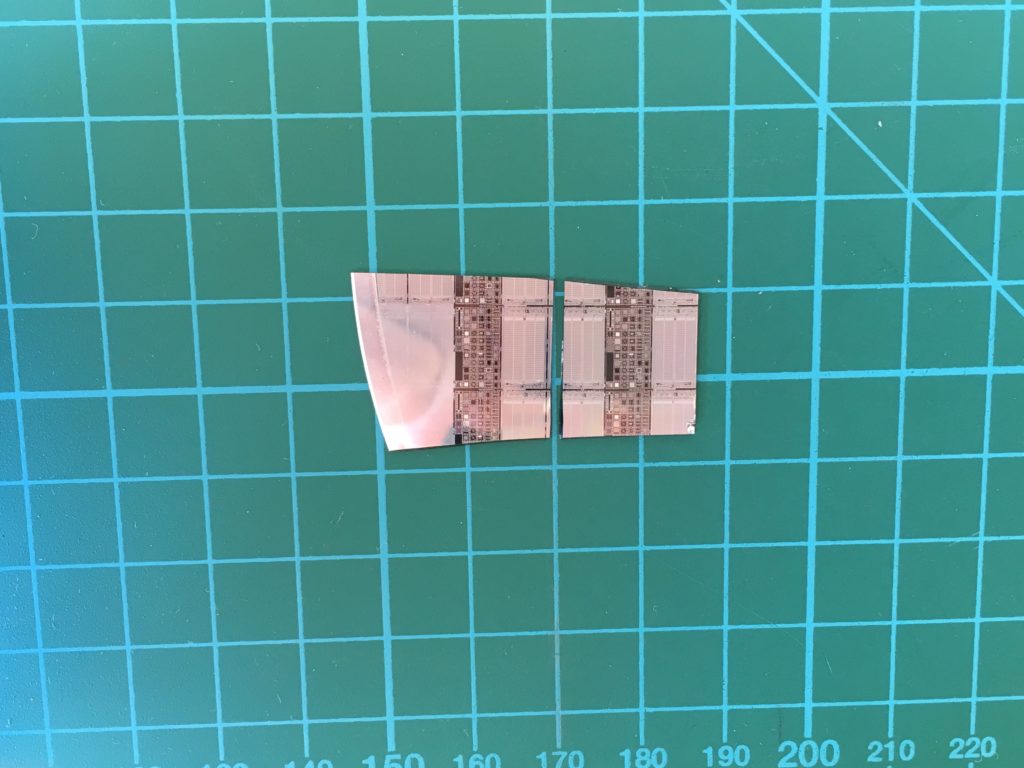

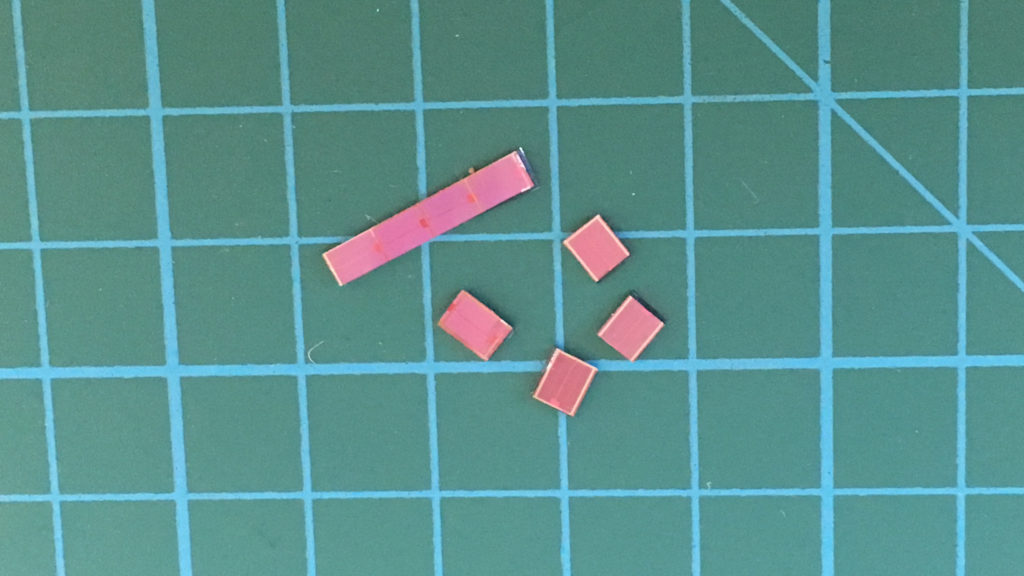

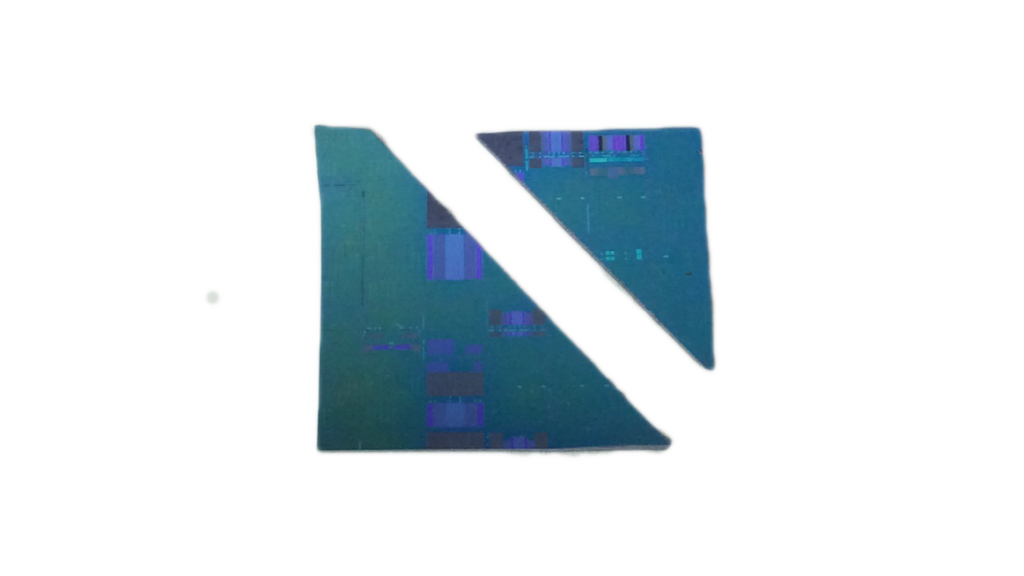

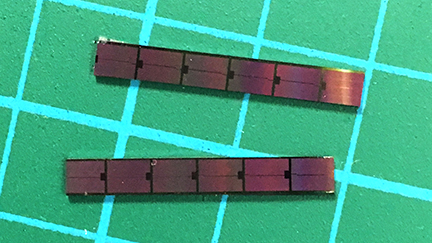

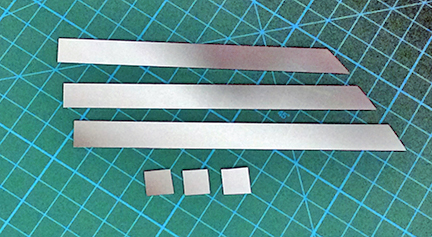

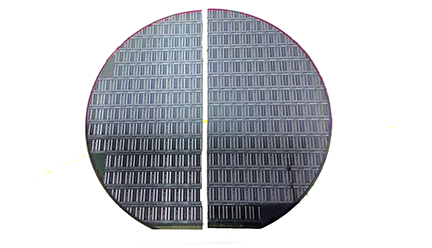

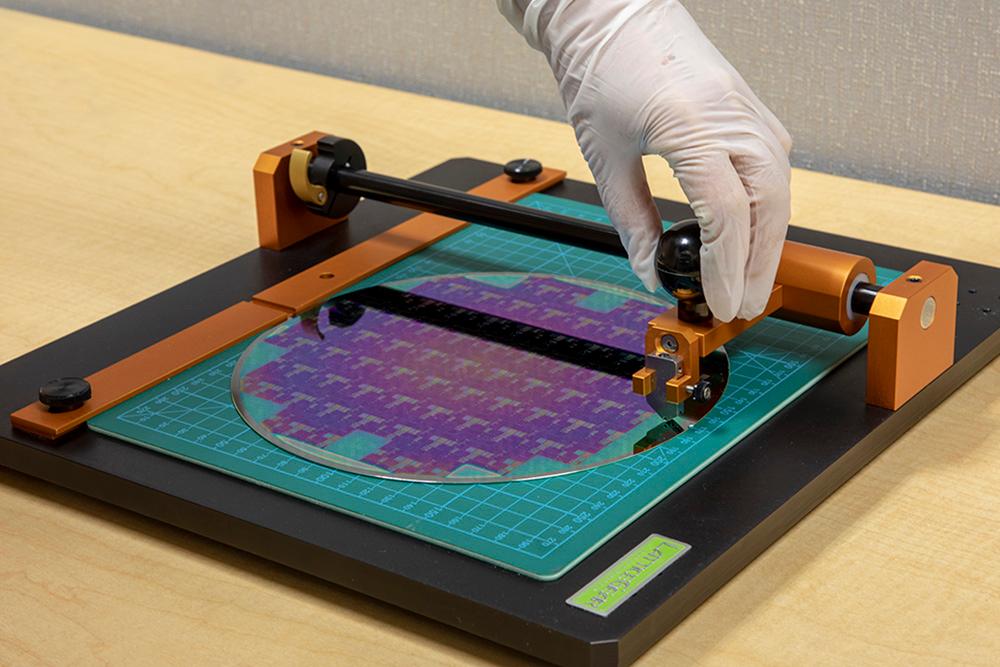

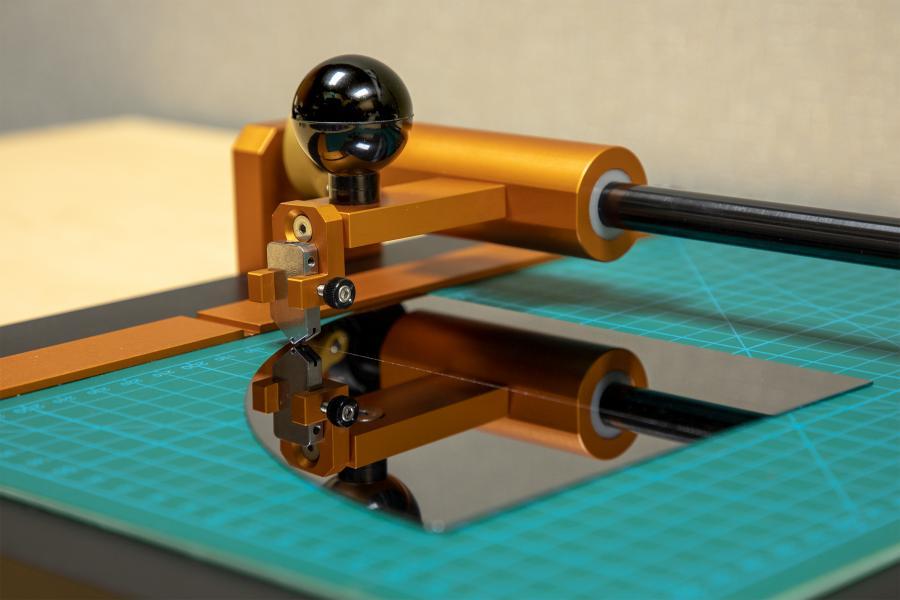

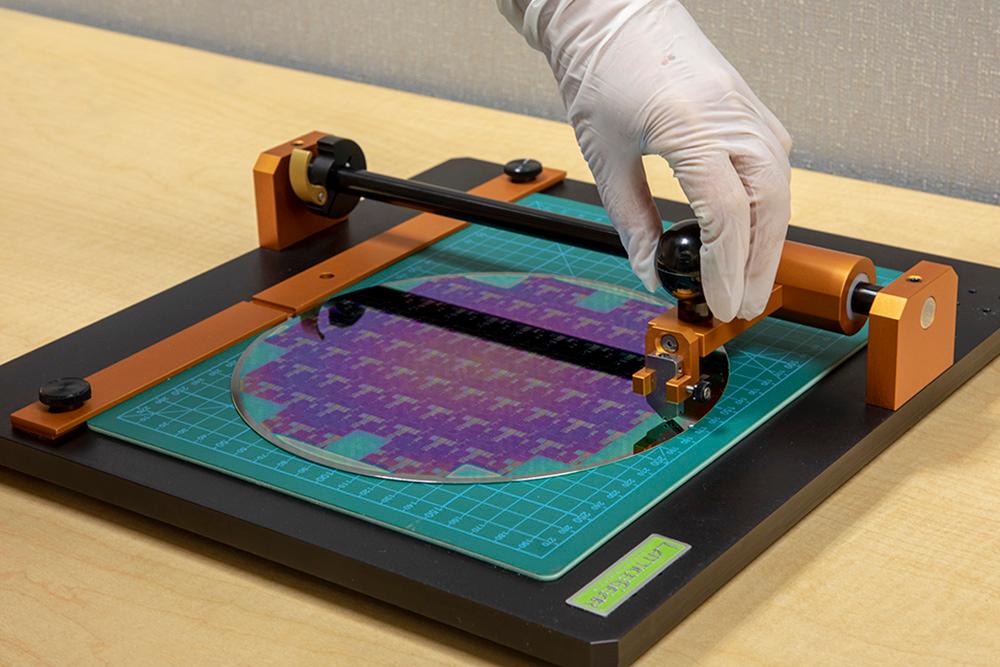

The FlexScribe Station is a super-fast, simple method for downsizing wafers and samples by scribing on the topside. It uses a carbide scribing wheel mounted to a sliding scribing mechanism that always makes a straight scribe. This system is used to scribe a wide variety of materials without restrictions on shape, including glass slides, coverslips, silicon, III-V, sapphire and other crystalline and brittle materials. It can address very small samples down to 5 mm up to 300 mm wafers.

The standard tungsten carbide cutter installed on the FlexScribe is a great for a wide variety of samples including silicon, glass, GaAs and other crystalline materials. LatticeGear recommends:

- PCD-ND120 diamond cutter for very thin glass, tempered glass and hard materials such as sapphire

- TC-ND153 For applications cleaving 100 silicon at 45 degrees and for thick glass.

For recommendations contact lg@latticegear.com or call +1-503-828-0040