LatticeAx

LatticeAx Options Package

Make sure you have everything to set up your cleaving workflow. This package includes 2 spare LatticeAx diamond indenters and everything necessary for cleaving large substrate, wafers and pieces.

Small Sample Cleaver

Using simple mechanics, the small sample cleaver (SSC) uses a novel sample holder and a cleaving platform to safely cleave samples into chips as small as 2x2 mm.

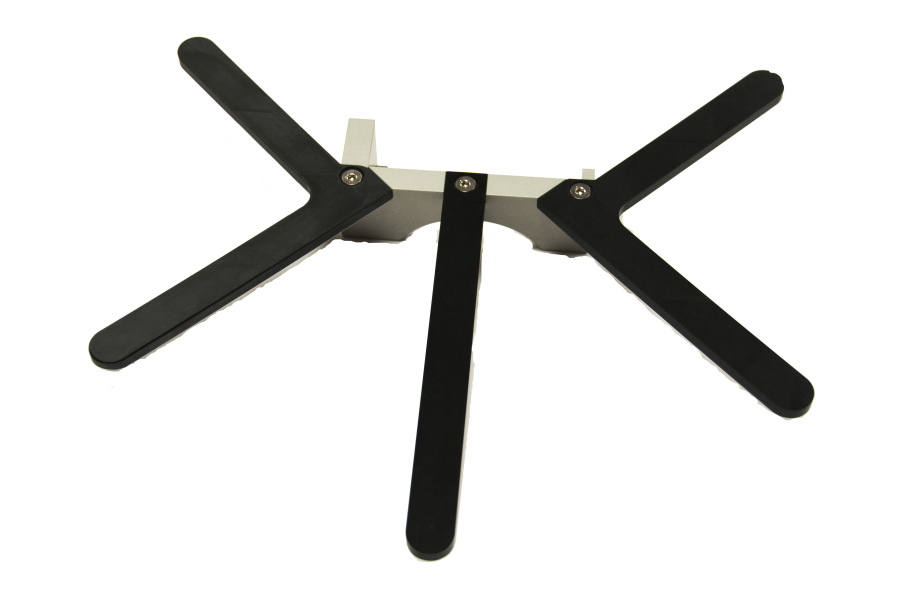

Large Sample Platform

Add the Large Sample Platform to any LatticeAx Indenting and Cleaving System to support large samples or a whole wafer up to 300 mm. This provides additional stability for a clean and accurate sample.

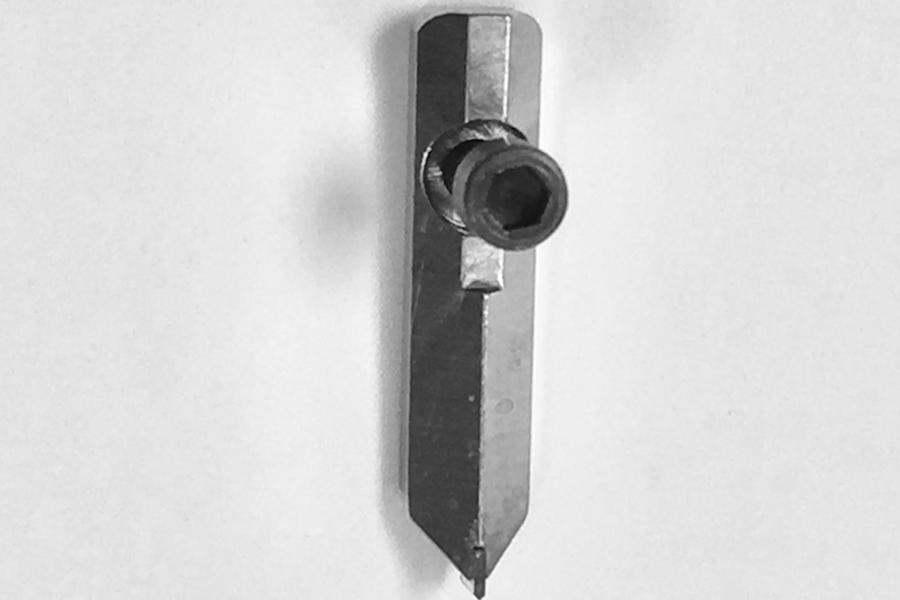

LatticeAx Standard Diamond Indenter

Diamond indenter for the LatticeAx. Standard 1 mm indent. Good for a wide variety of samples. Polished end for improved positioning.

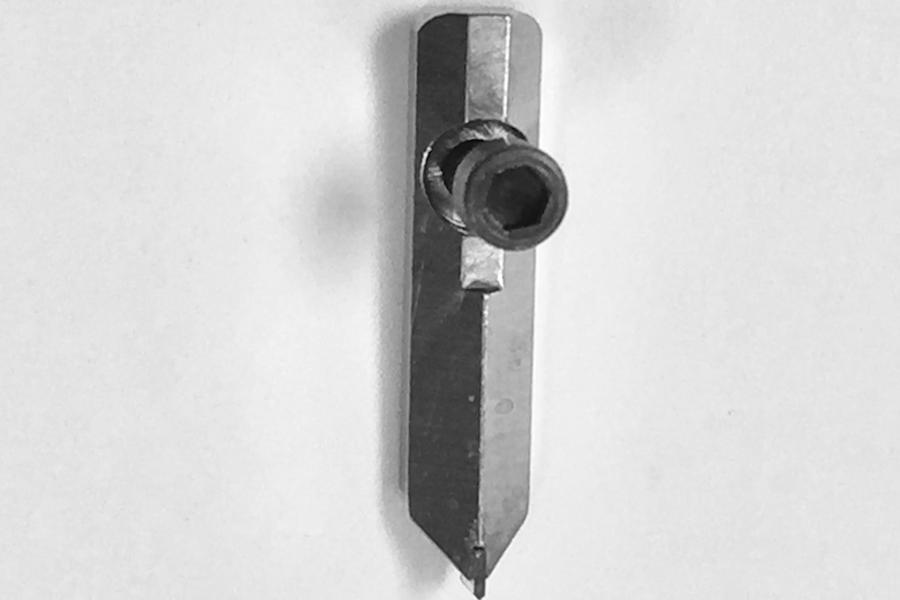

LatticeAx “Short” Indent-Diamond indenter

The LatticeAx short diamond indenter is designed to make an indent approximately half the length of the standard diamond indenter (0.5mm). The LatticeAx short indent diamond indenter comes pre-aligned in the same shank as the standard indenter. There is no change in installation or handling procedures.

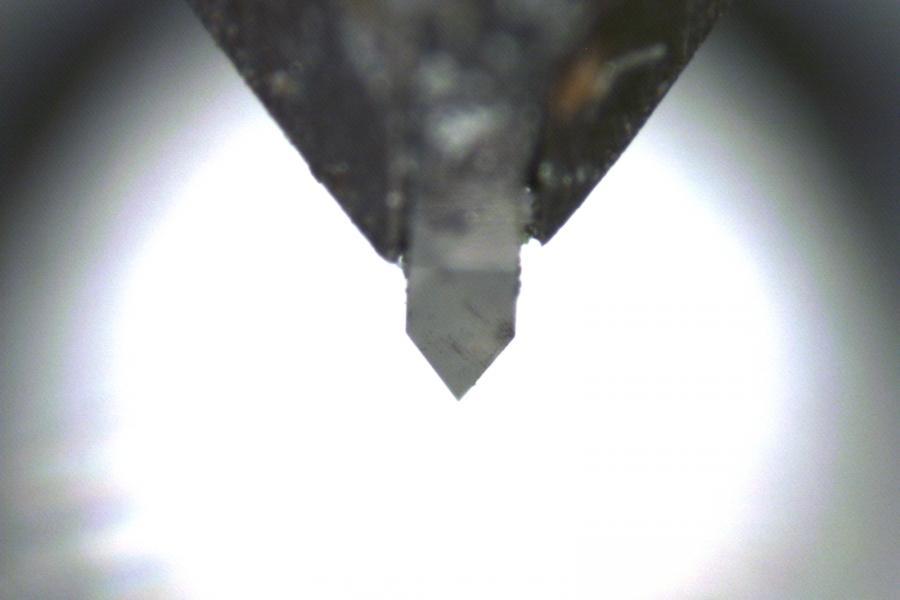

LatticeAx high angle diamond indenter

High angle diamond indenter for the LatticeAx. Standard 1 mm indent. Polished end for improved positioning. Indenter is has a 60 degree angle and is used for applications that routinely require cleaving targets with ultra high accuracy. Lifetime not guaranteed. Do not use on hard materials such as sapphire and SiC.