Semiconductor Use Cases

Semiconductor Publications

Publications (for copies, contact lg@latticegear.com) or for downloadable copies of these publications you must be registered and signed in

Download

Cleanroom Technology, Clean Cleaving

Download

Global Foundries, A Controlled Mechanical Method for MEMS Decapsulation (poster)

Download

University of Copenhagen, Successful Cleaving of Delicate Nanostructures

Download

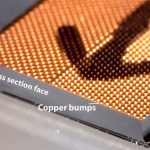

ISTFA 2014, Conference Proceedings Advances in FIB-SEM Analysis of TSV and Solder Bumps - Approaching Higher Precision, Throughput and Comprehensiveness

Download

Solid State Technology, From Transistors to Bumps: Preparing SEM Cross-Sections by Combining Site-specific Cleaving and Broad Ion Beam Milling

Download

EDFA Journal, Cleaving Breakthrough: A New Method Removes Old Limitations