Site Specific Cleaving of Structures with Rotated Lithography Using the LatticeAx

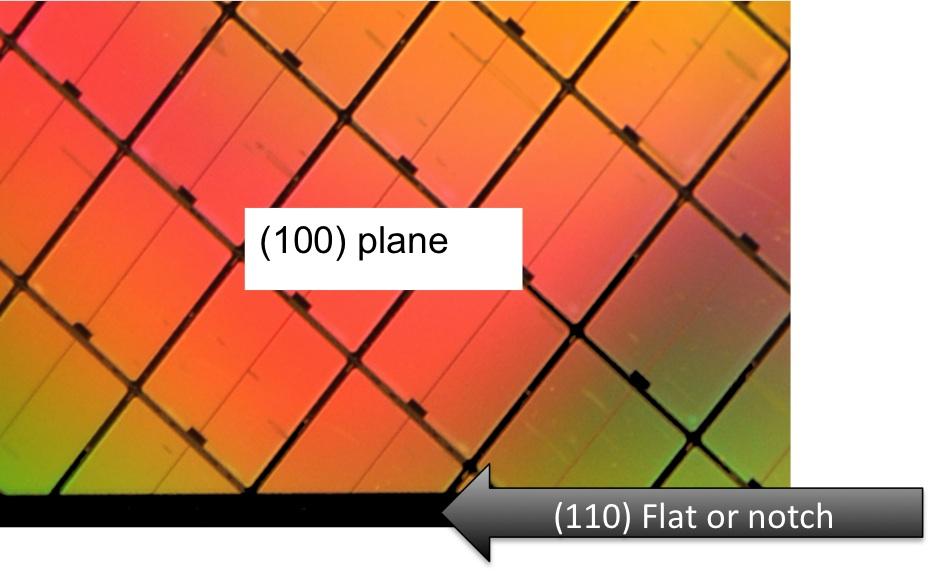

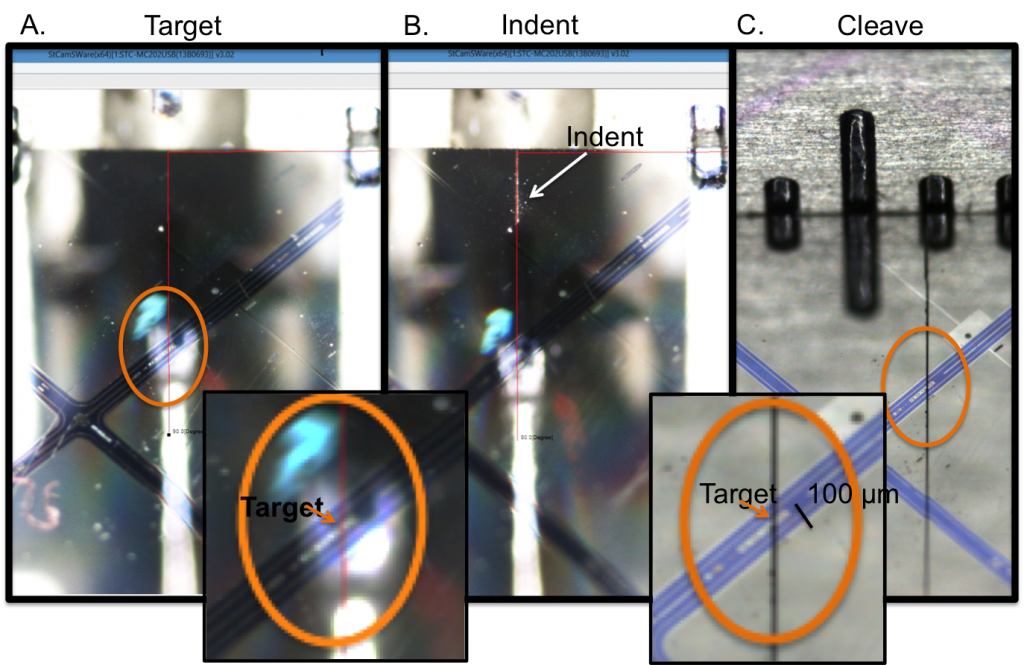

The LatticeAx was used to cleave a specific site on the sample without the luxury of features that are aligned perpendicular to the sample's leading edge. Although the silicon is <100> the pattern shown is rotated 45 degrees. This makes it more challenging to target features. A process was developed to target the area of interest and cleave.

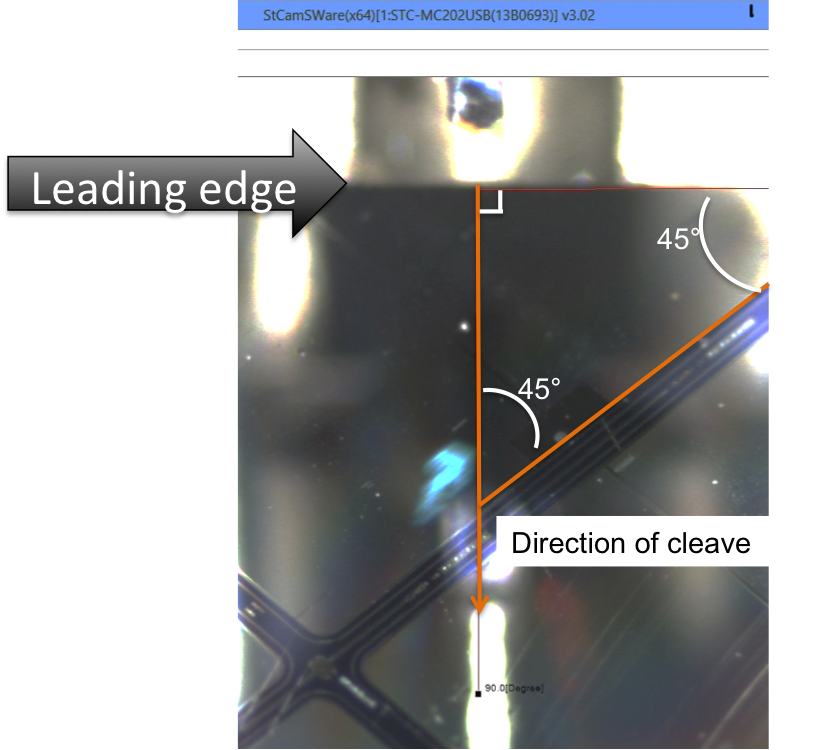

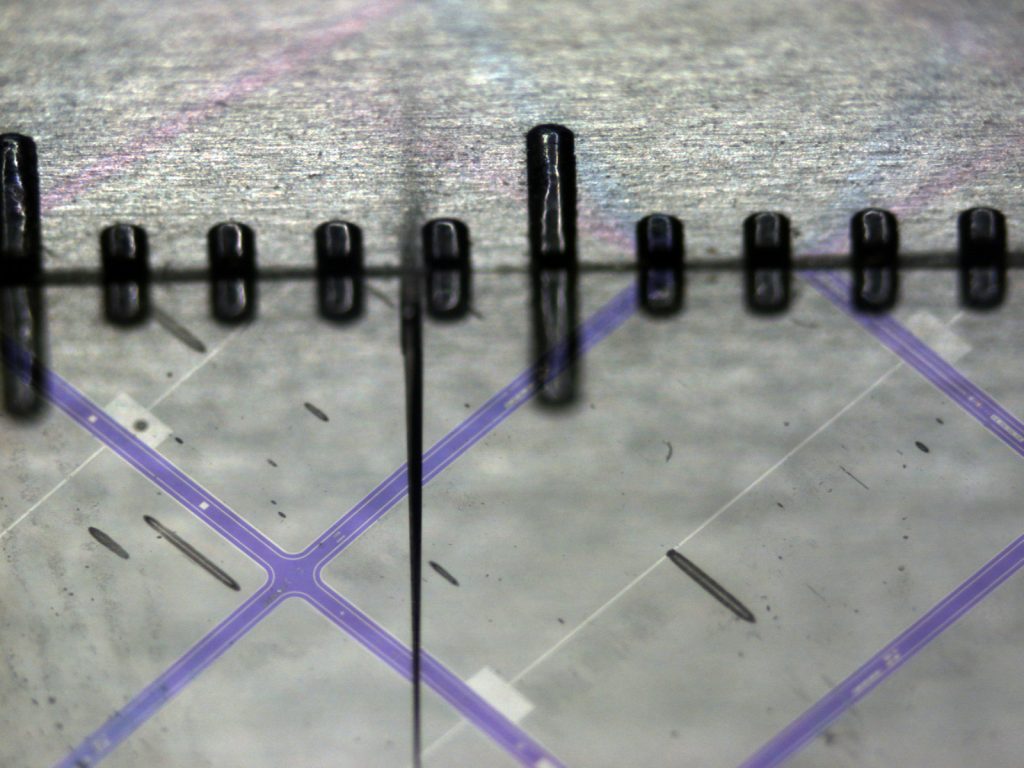

For the best targeting accuracy, the sample must have a clean leading edge. If the leading edge is not straight or is too rough, the target will be missed unless it is very close to to the indent. For all silicon, the direction of the cleave will always be 90 degrees to the leading edge. This property allows the direction of the cleave and location of the target to be visualized by drawing a line perpendicular to the leading edge. The indent is made on the surface of the silicon and on top of the drawn line. The cleave propagates from the indent, perpendicular to the leading edge of the sample.

Download the full applications note here:

[wpdm_package id='4230']