Professional Glass Cleaving & Scoring Tool

Glass Cleaving Applications

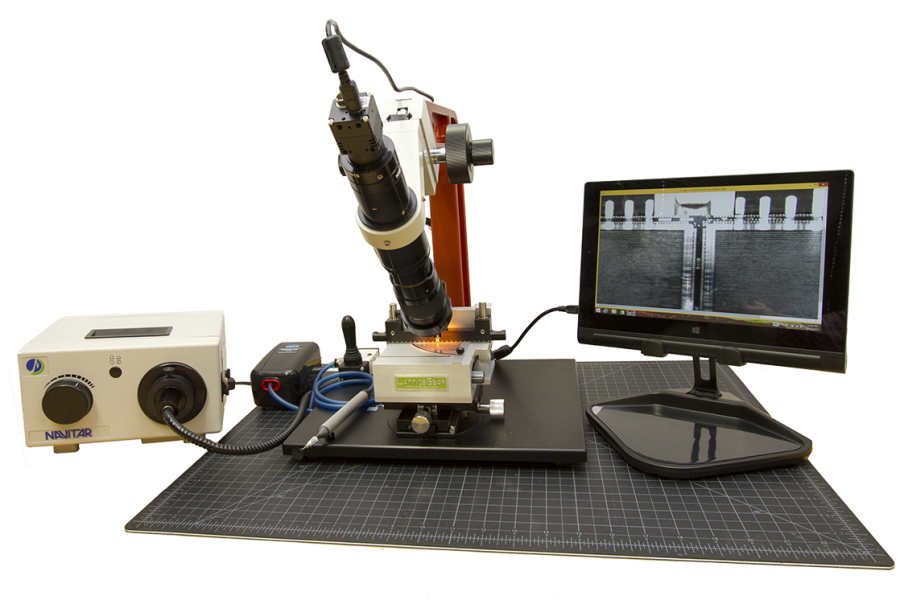

LatticeGear designs, manufactures, and sells cleanroom compatible benchtop tools for cleaving a wide variety of substrates, both crystalline and amorphous, including silicon, GaAs, InP, sapphire, and glass. When developing tools and processes, we learned that scribing parameters such as scribe angle and depth are critical to the quality of the cleave.

For glass wafers and substrates, stray cracks will occur if the scribing conditions are not optimized. This results in unwanted lateral crack propagation that changes with angle of the scribe wheel or scribe tip, scribing force and other variables. WATCH VIDEOS

Eagle XG Glass Substrate

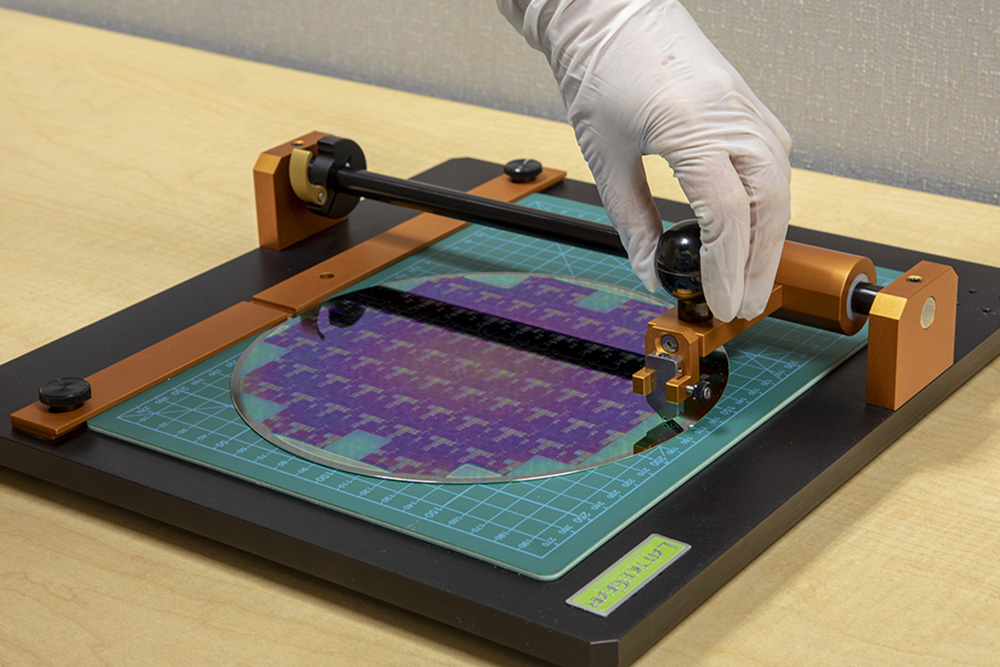

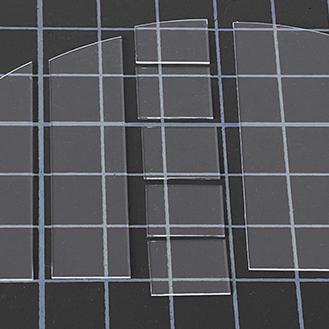

Eagle XG glass substrates used in the LCD industry were purchased to see whether the cleaving process could be modified to downsize larger samples. Using the FlexScribe and a diamond cutting wheel, followed by 3 point cleaving with the LatticeAx, the wafer can be cut cleanly without particulate contamination or fractures in unwanted directions. A three point cleave is achieved by creating pressure on a sample underneath the scribe and two pressure points on top of the sample, equidistance from the scribe.The image on the right shows the cleanliness of the cuts. The 1cm2 die were made by scribing with the FlexScribe and cleaving the samples with the LatticeAx which created clean, vertical facets.

Thick, Thin and Hard Glass

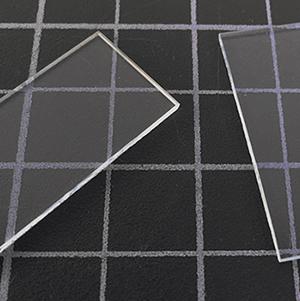

On the right are examples of hard, 2 mm thick, fused quartz glass cleaved using the FlipScribe. The FlipScribe scribes the backside of the sample without touching the surface. Follow the link to learn more about the features and benefits of the FlipScribe.

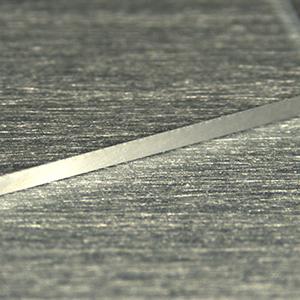

The thin coverslips (120-160 microns thick) were cleaved with the FlexScribe configured with a cutting wheel embedded with diamond. It is designed specifically for very thin glass and hard samples such as sapphire.

Tempered Glass

We found that with a little skill and the right tools, even tempered glass can be cleaved. See our notes on how to cleave tempered glass Downsizing Tempered Glass

Solutions

There are just a few things to think about when choosing tools for cutting glass.

- What is my substrate size and thickness?

- Do I need mirror finish edges (typically needed for photonics devices)?

- Do I want to cleave samples for cross section analysis by SEM?

The solution may require one or more tools to get the job done. For instance:

- For downsizing large thin (<200 micron) glass wafers into 1 cm2 die, no mirror finish required. Use the FlexScribe with PCD diamond cutting wheel.

- For preparing samples that must have mirror finish facets for photonics or SEM analysis. Downsize with the FlexScribe or FlipScribe and make the final cleave with the LatticeAx.

- Preparing samples that have sensitive thin films on the surface. Use the FlipScribe backside scriber to downsize the samples. Make the final cleave using the LatticeAx to obtain mirror finish facets.

Products for Cutting Glass

Glass, because it is amorphous with no crystalline cleaving planes, can be difficult to downsize cleanly and safely. Based on your application, LatticeGear can recommend the right tool set. Please CONTACT US!

Scribing and Cleaving Tools

There are a number of accessories and consumables that will be important for your laboratory.

CleanBreak Pliers with 3 Sets of Jaws. After scribing you will need to cleave your sample. It is possible to cleave over a sharp edge but the pliers provide symmetrical force when breaking the glass. Cleanbreak pliers are used for samples 20mm/.75" and larger.

Videos

Watch videos showing the operation of the scribing and cleaving tools and systems.

Publications

Publications (for copies, contact lg@latticegear.com) or for downloadable copies of these publications you must be registered and signed in