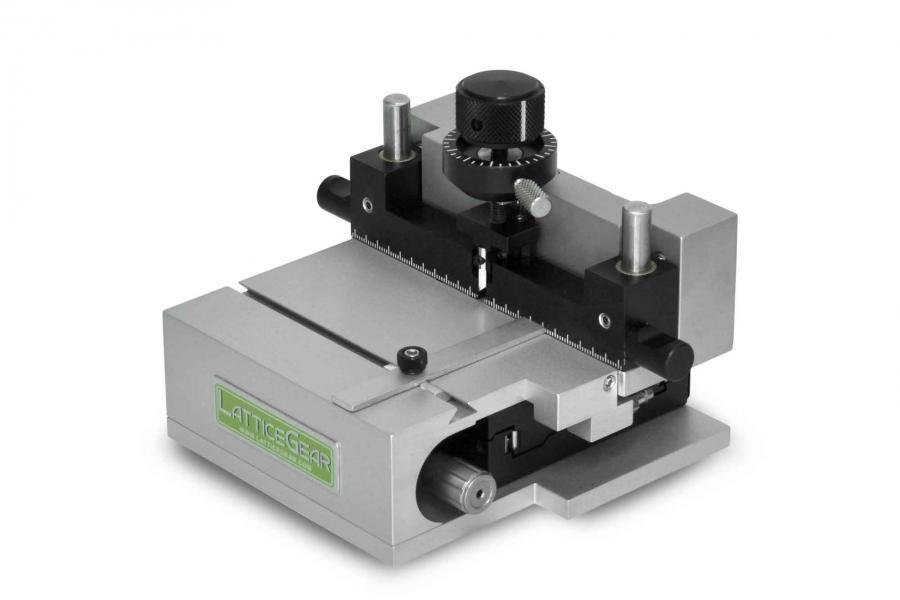

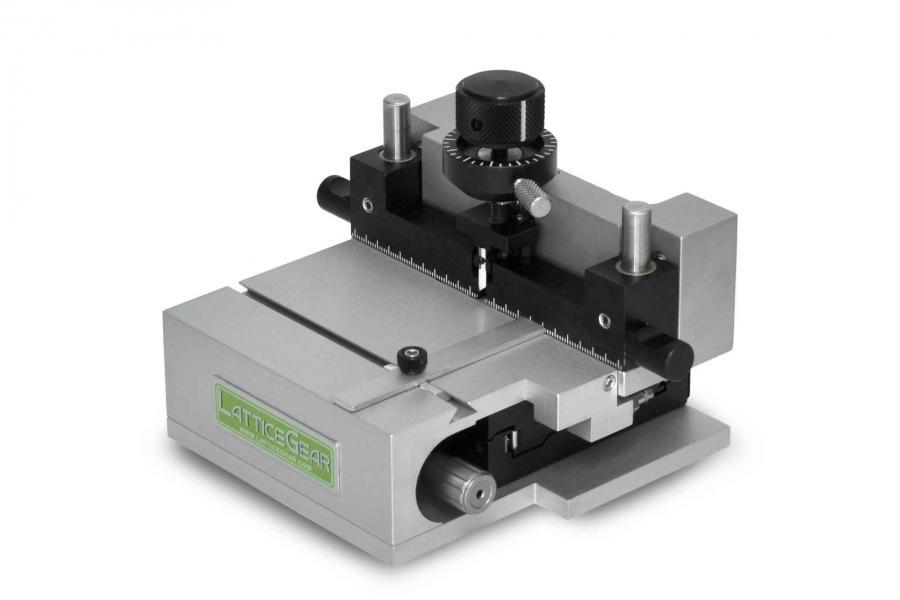

Base Indent and Cleaving System

By using the Patented LatticeAx® base platform, every user can achieve high quality cleaves within 2 minutes for samples that vary in size, thickness and material. Use the 120 to cleave silicon, GaAs, glass, sapphire, hard disk drives and other substrates.

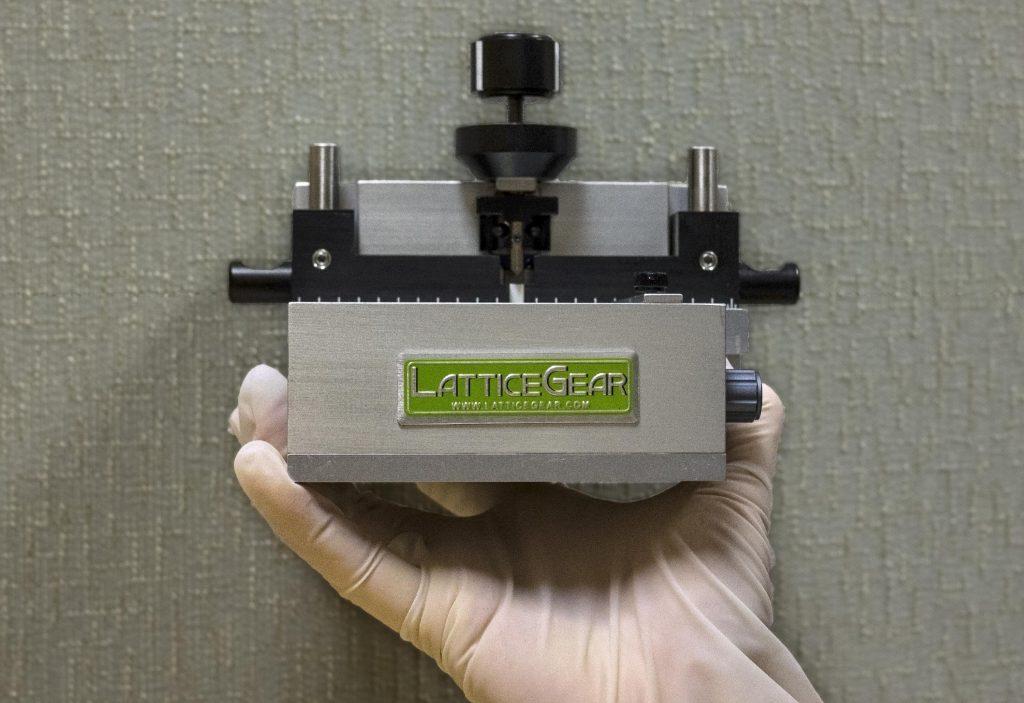

With the LatticeAx® 120, you literally have in the palm of your hand a versatile and powerful cleaving tool for downsizing and cross sectioning a wide range of substrates including Silicon, GaAs, InP, Sapphire, Glass, and Hard Disk Drives. With the LatticeAx, you can cleave your samples as they are, without additional preparation, and strict rules on the size, shape, thickness, edge quality and material type.

Learn more about the LatticeAx product line

To download a copy of the LatticeAx® 120 Datasheet register and/or sign in.

CLICK HERE to go to the corresponding webpage at Ted Pella.com

Benefits

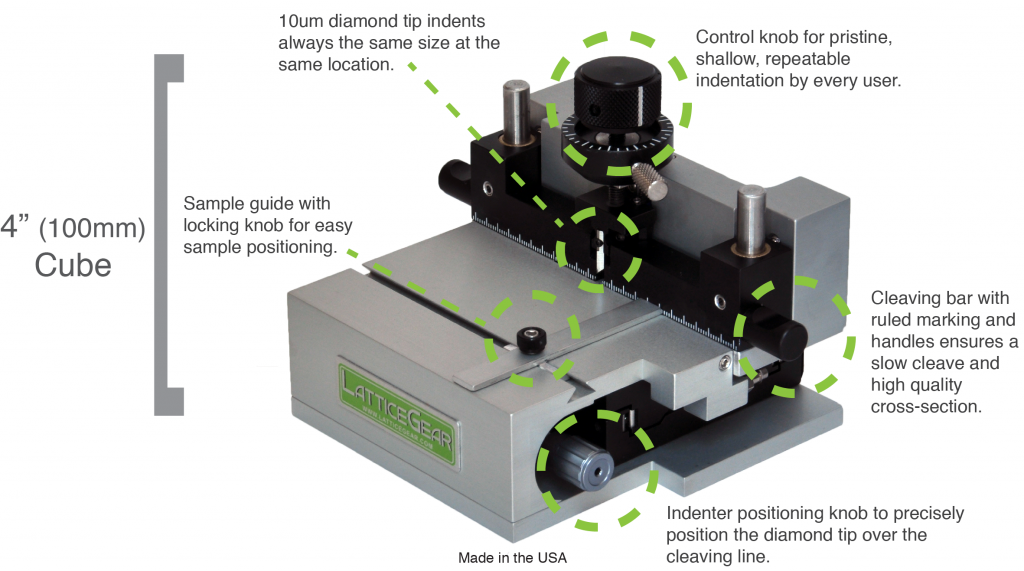

- Accurate and Repeatable Indent and Cleave

- Clean and high quality mirror finish cleaved face

- Simple to operate

- No maintenance contracts

Features

- Small footprint (4″/100mm cube), easy to transport/move

- Purely mechanical design, no power required to operate the tool

- Diamond indenter with polished face for accurate positioning

- Clock dial for indent calibration

- Position control of indenter with 5 µm step size

- Vacuum pump to secure sample with pnuematic valve switch