Learn About Cleaving With LatticeGear

Cutting Glass

Glass wafers are used for a wide variety of applications from semiconductor processing to microfluidic chips used for biotechnology devices. As a result, LatticeGear™ receives many questions about solutions to cleanly and quickly dice wafers without costly equipment. There are many different types of glass and knowing the glass composition, along with substrate size and thickness, aid in determining the best tools and process for dicing. These topics will be covered in this post.

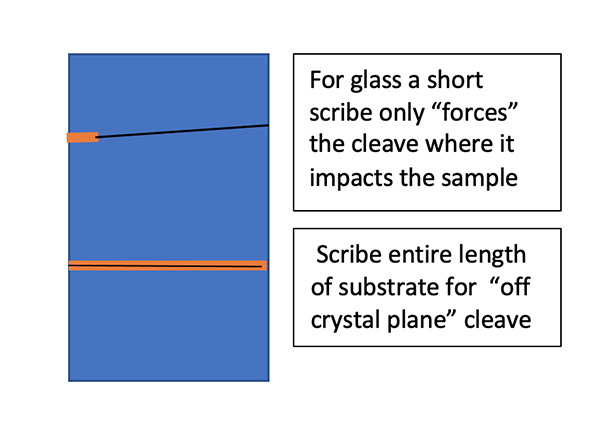

Cleaving is the act of splitting one substrate into two. As glass is amorphous, when it is cleaved there is no crystal plane to define the direction of the “split” or break. Therefore, unless you force the sample to cleave by scribing across the entire length of the desired cleave, it will not be straight. Figure 1 shows the short scribe/indent in orange and the direction of the break or cleave in black. The short scribe results in a break that is not orthogonal to the substrate edges. The scribe that goes across the entire length of the desired cleave breaks along the scribe line.

Achieving a mirror finish facet

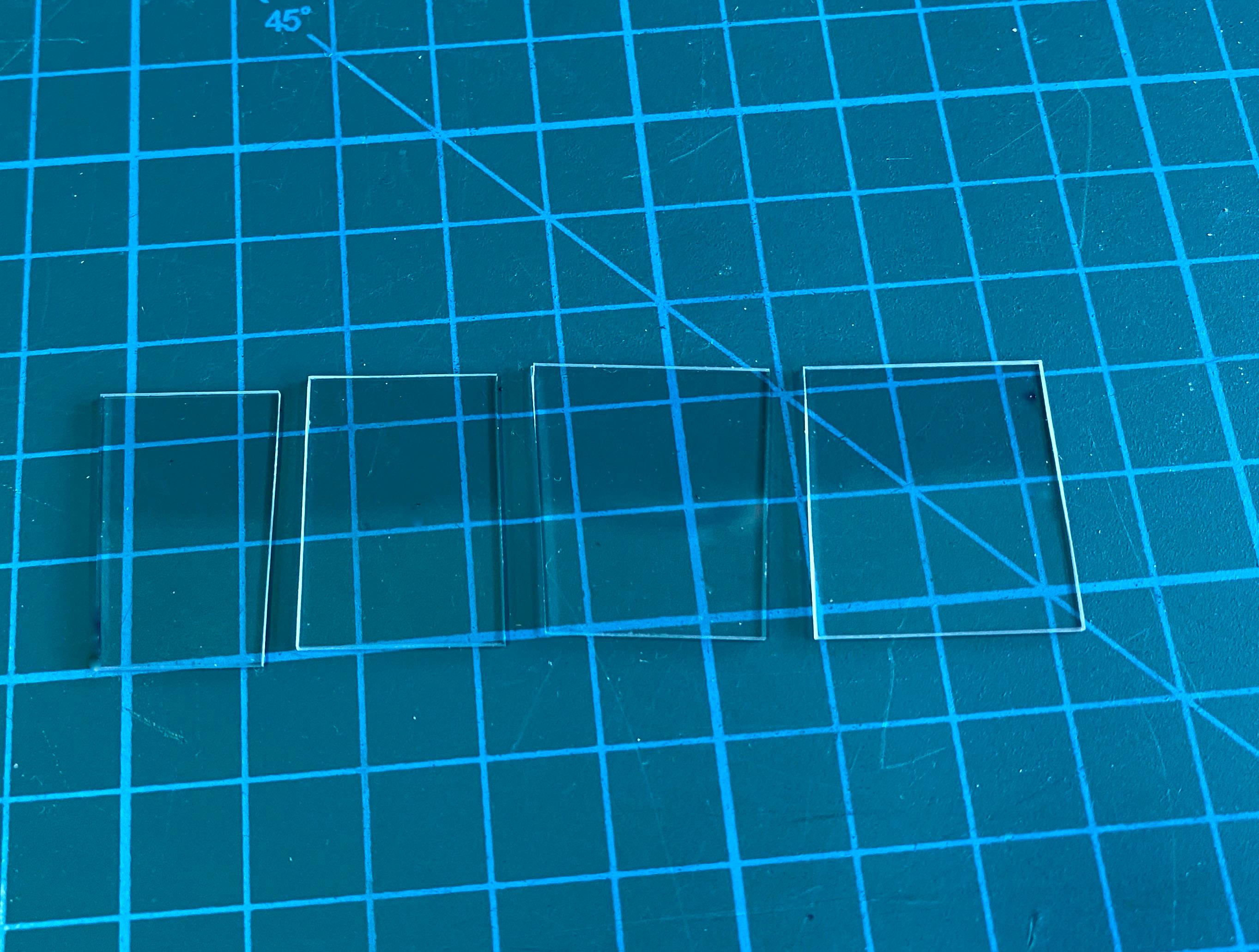

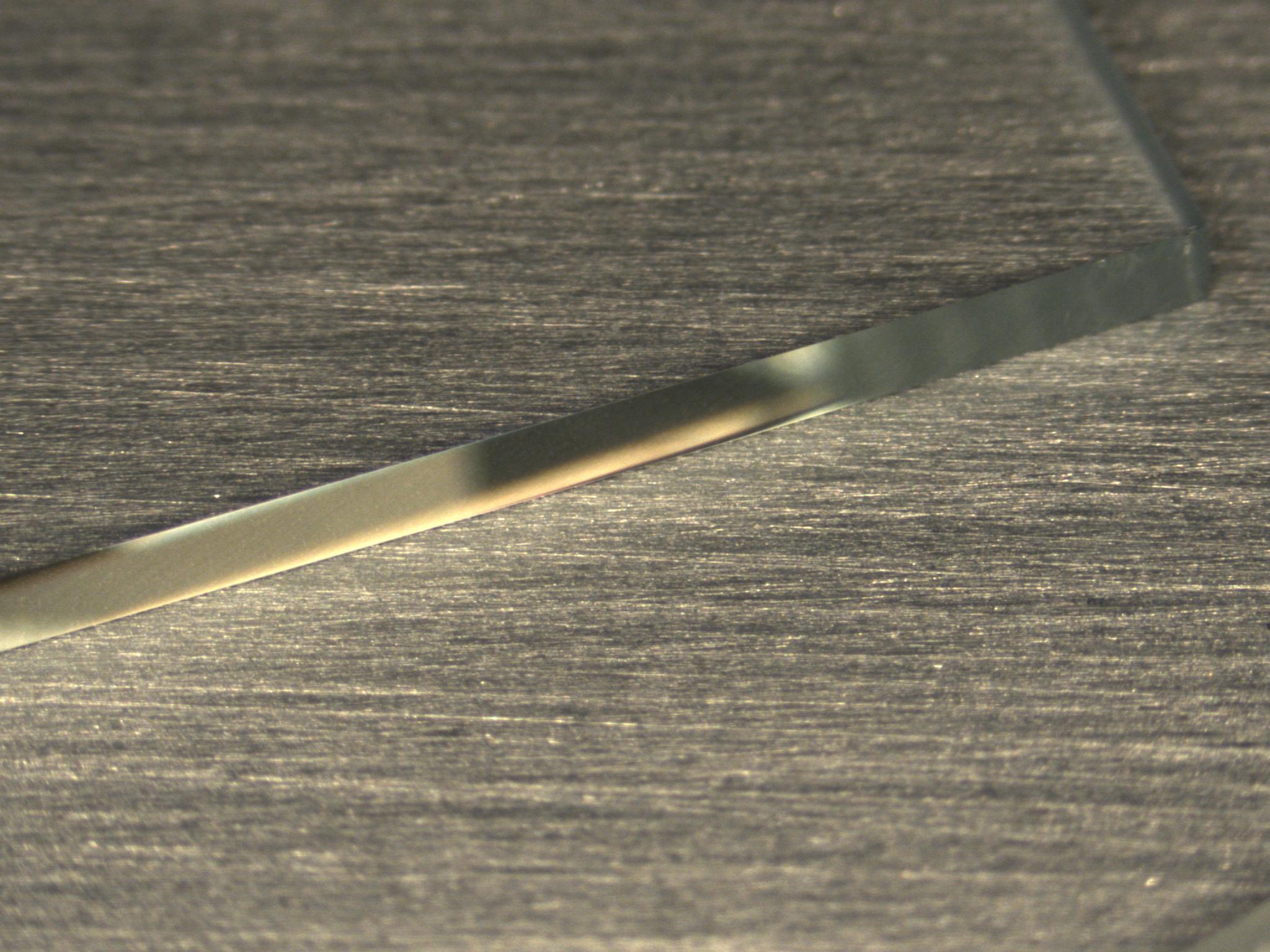

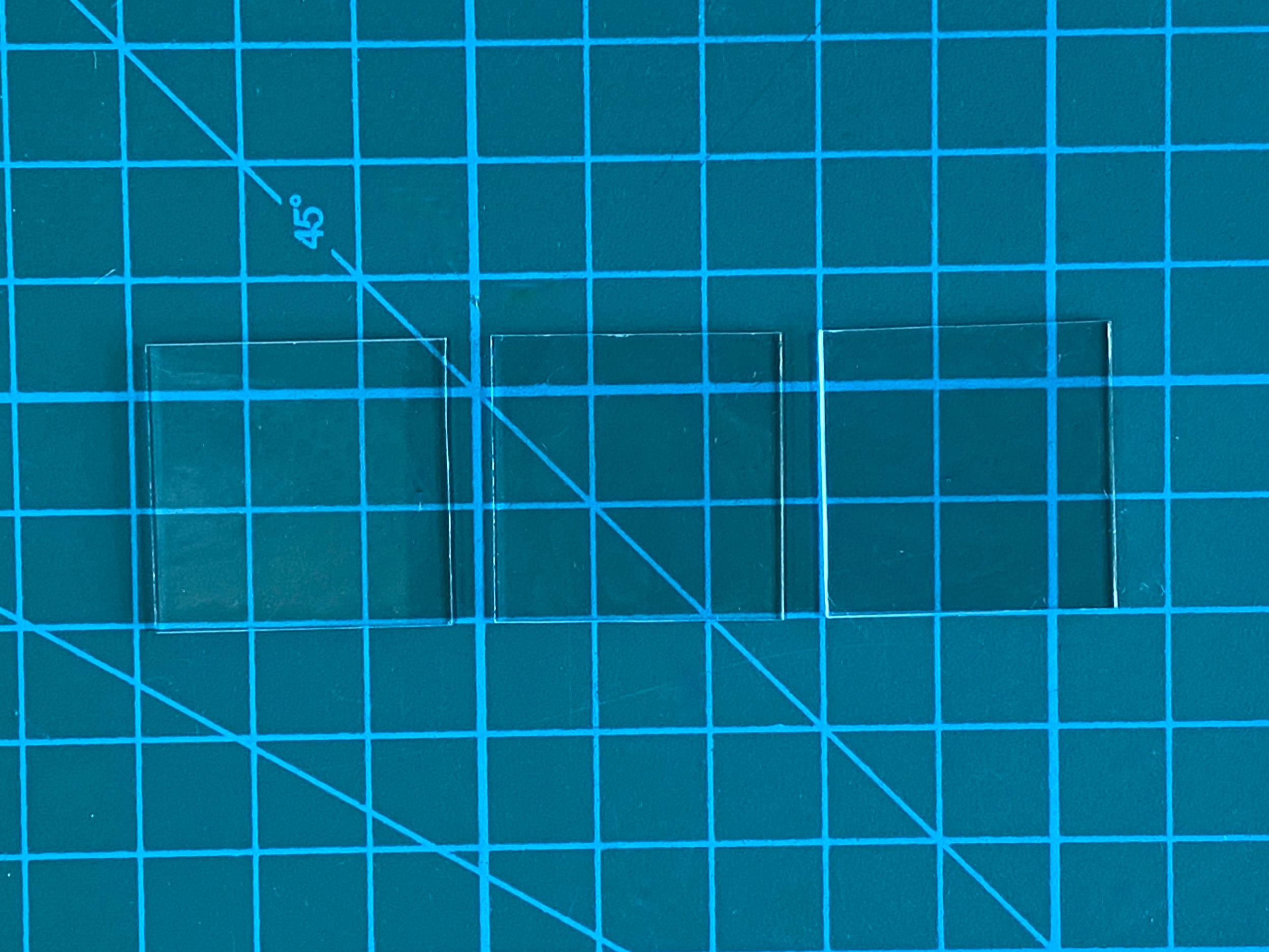

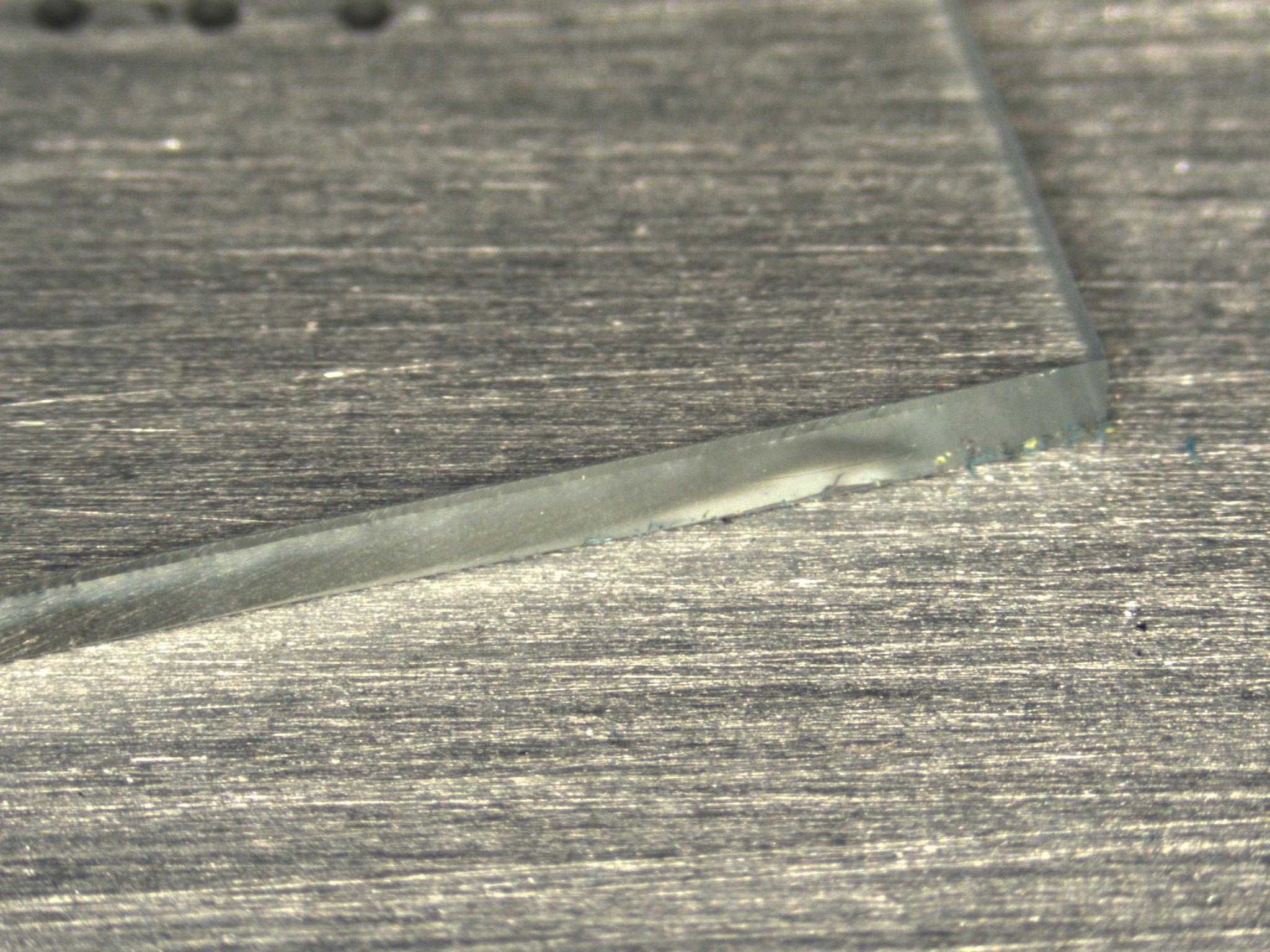

You might ask, why would you ever do a short scribe on glass? If you want a perfect mirror finish facet. Figure 2 shows a standard borosilicate glass slide cleaved with the LatticeAx®. Note that the pieces are not perfectly rectangular. The LatticeAx yields a mirror finish facet needed for photonics applications and scanning electron microscope (SEM) imaging in cross-section. Figure 3 shows the same type of glass the scribe made across the entire length of the slide. This forces the sample to cleave along the scribe line and yields rectangular samples. The cleaved facet will show some damage from the scribing process but if the objective is to make rectangular samples for experiments or further processing you will need to use the long scribe process.

Obtaining edges with orthogonal edges

Figure 3 shows the same type of glass the scribe made across the entire length of the slide. This forces the sample to cleave along the scribe line and yields rectangular samples. The cleaved facet will show some damage from the scribing process but if the objective is to make rectangular samples for experiments or further processing you will need to use the long scribe process.

Important Tips

Scoring/scribing glass

You will get the best cut by making a single scribe with gentle even pressure that produces a fine, visible line on the glass. You do not want to go so deep that fractures are observed.

Cleaving/breaking

When you split your pieces after scribing, the highest success and best facets will be obtained if you use the rule of halves. The rule of halves states that you cut is most likely to run straight when you have equal amount of glass on either side of the scribe. In short, avoid cutting a thin strip off of a large plate of glass.

Find more helpful information on our webpage on Cleaving Glass.

Don't see your application here, CONTACT US for a recommendation.

Product Recommendations

LatticeAx 120, 220, and 420 (up to 300 mm wafer)

FlipScribe (up to 4” wafer)

FlexScribe (up to 300 mm wafer, standard borosilicate glass)

FlexScribe with diamond scriber (up to 300 mm wafer, quartz glass, thin glass)

Carbide cutter cleaving kit (general glass cutting)

Handheld scribers (general glass cutting)

Cleanbreak Pliers with 3 sets of jaws 6” handle (cleaving glass and crystalline substrates)

Cleanbreak Pliers with 3 sets of jaws 8” handle (cleaving thick glass and sapphire)